Solder Paste Automatic Management System with MES Traceability for ODM/OEM Quality Control

Printed circuit board assembly quality control is becoming increasingly critical in the rapidly developing electronic manufacturing industry. As an indispensable material in the surface mount process (SMT), solder paste directly impacts the quality of welding due to temperature and humidity management, storage time, mixing uniformity, and temperature regeneration records during use. To this end, the solder paste automatic management system came into being and was deeply integrated with the MES system to form a complete traceable, automated, and intelligent production process. This is a win-win revolution of cost reduction, efficiency improvement, and quality assurance for ODM and OEM printed circuit board manufacturers.

1. Traditional Solder Paste Management Pain Points

In the traditional PCB assembly and manufacturing process, solder paste management often relies on manual labor, and the following problems are prone to occur:

-

- Non-compliant storage temperature and humidity affect solder paste activity

- It is difficult to control the temperature regeneration and mixing time accurately

- Missing solder paste usage records affect traceability

- Mixed use of multiple batches of solder paste leads to reduced yield

- These problems may only appear after PCB board testing mass production, resulting in significant rework costs and reduced customer satisfaction

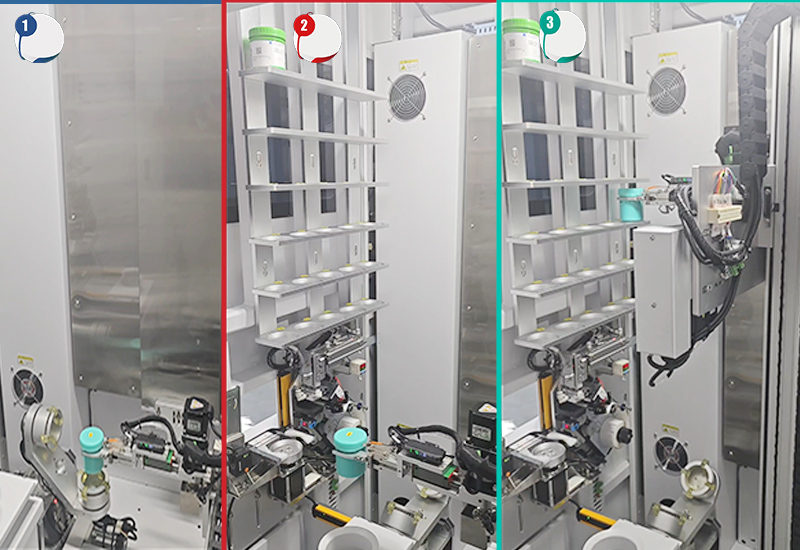

2. Composition and Functions of Solder Paste Automatic Management System

Modern solder paste automatic management equipment system mainly includes the following core modules:

(1) Intelligent Constant Temperature Storage Cabinet

Ensure that the solder paste is stored in a set temperature and humidity environment, and record the time of each solder paste being put in and taken out.

(2) Automatic Reheating and Stirring System

After the solder paste is out of the warehouse, it is automatically discharged into the reheating zone and timed, and then the equipment automatically stirs at a fixed time to avoid human errors.

(3) Scanning Traceability System

Each solder paste is attached with a tag, and the MES system can read its operation records, including:

-

- Storage time/temperature

- Reheating start and end times

- Stirring times and intensity

- Online use time and location

- Personnel use, tracing the source of users

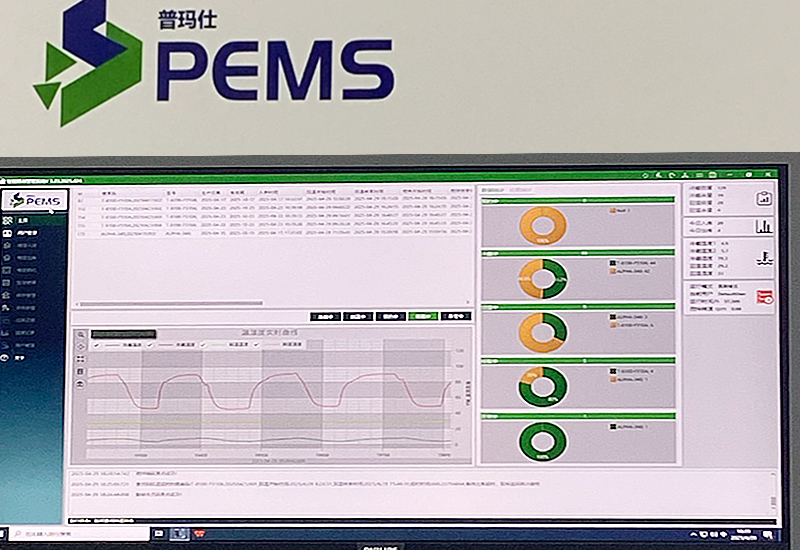

3. Seamless Connection of MES Traceability System

MES (Manufacturing Execution System) is vital in solder paste management. Its functions include:

-

- Record and display the complete life cycle of each batch of solder paste

- Connect SMT machines to control non-compliant solder paste from going online

- Generate quality analysis reports and abnormal warnings

- Link with ERP system to optimize procurement and inventory

4. Advantages of Application Under ODM/OEM Mode

For ODM (original design manufacturer) and OEM (original equipment manufacturer), the introduction of automatic solder paste management system has significant significance:

Enhance Customer Trust

When customers entrust printed circuit assembly production, they are most concerned about circuit board manufacturing consistency and quality control. Automated solder paste management can provide clear and auditable data to enhance cooperation confidence.

Reduce Manufacturing Risks

When multiple batches and categories of products are PCB SMT simultaneously, the system ensures that the solder paste is not mixed and mixed, effectively preventing mistakes.

Improve Printed Circuit Board Production Efficiency

Reduce human intervention, synchronize the reheating and stirring processes automatically, and avoid waiting and repeated operations.

Data Supports Optimized Design

ODM manufacturers can use solder paste usage data to reversely optimize the patch process and improve design for manufacturability (DFM).

5. The Only Way To Smart Manufacturing

SCSPCBA’s printed circuit board manufacturing plant achieved the following changes after introducing the solder paste automatic management system:

Abnormal solder paste usage rate decreased by 98%

SMT first piece yield increased to 99.8%

Customer complaints decreased by 90%

Achieved 7×24 hours of unmanned solder paste management operation

Although solder paste is small, it affects the box build assembly process. For ODM/OEM circuit board manufacturers who pursue high quality and strong delivery capabilities, the deep integration of solder paste automatic management equipment and MES system is not only a key step in lean PCB board production, but also an important milestone in realizing SCSPCBA digital factories and smart manufacturing.

Through comprehensive monitoring, SCSPCBA data-driven and system collaboration, solder paste management is no longer a pain point, but a highlight of printed circuit assembly quality control.